- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Transforming Automation through Intelligent Motion Solutions

Dorner offers a wide variety of industrial, aluminum frame and sanitary, stainless steel frame conveyors. With fabric belt, modular belt, and flexible chain options, our conveyors can be configured as straights, curves, inclines, declines, and Z-frames. All Dorner conveyors are built-to-order and ship in as little as 72 hours!

Create your own custom conveyor with Dorner’s industry leading CAD/Configurator software. With DTools, designing a conveyor that meets your specific application is quick and easy. Submit a request for complete custom systems or replacement parts for your existing conveyor, and get a free quote and CAD design fast!

DualMove

The new DualMove Pallet System features twin timing belt-driven pallets for accurate product transportation and positioning. With expanded modules and weight ratings, this pallet system is ideal for a wide variety of applications in manual and automation manufacturing.

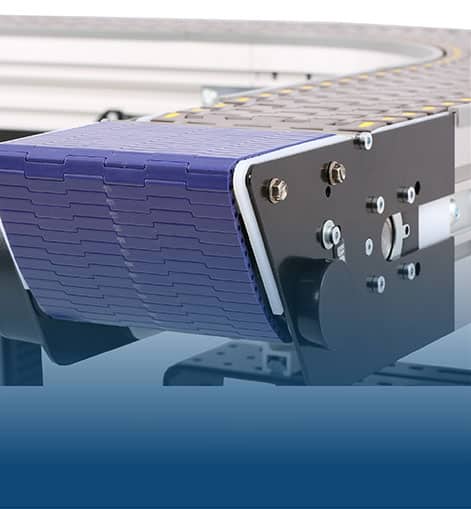

AquaGard GT

The AquaGard GT is the first joint venture between Dorner and Garvey. With a flexible chain belt and highly modular design, this sanitary stainless steel conveyor is the perfect solution for packaged foods, bottling, and battery manufacturing applications.

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy